Motors: Creating Air Flow and Rotation

10 Oct 2024

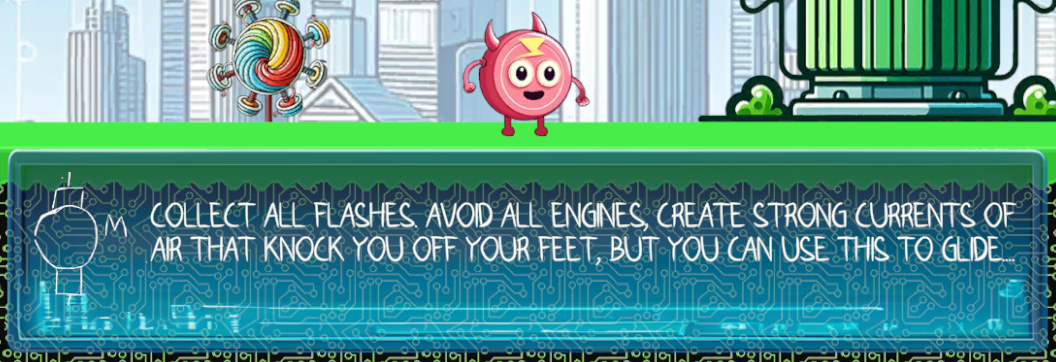

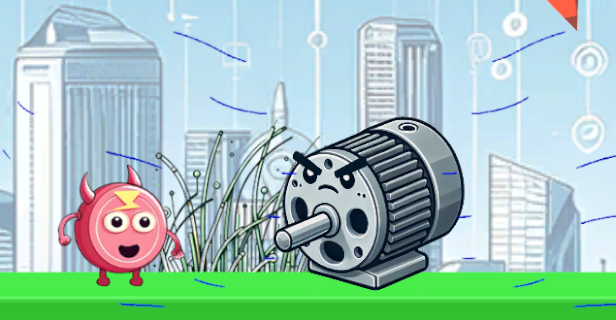

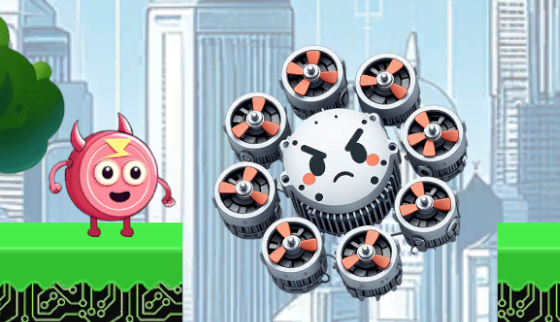

Electric motors are devices that convert electrical energy into mechanical energy, creating rotational motion. Depending on the type and design, motors can be used for a variety of purposes, including moving machinery, driving fans and pumps, and creating strong air flows that create obstacles for the player to complete a level. Let's take a closer look at how motors create motion and what types of rotation and air flows they can create.

1. How an Electric Motor Works

An electric motor works based on the interaction of magnetic fields and electric currents. The main components of a motor are:

Rotor: The moving part of the motor that rotates and transmits rotational motion to the shaft.

Stator: The stationary part containing the windings or permanent magnets that create the magnetic field.

Commutator or Electronic Controller: Controls the direction of the current in the rotor windings, ensuring continuous rotation.

When an electric current passes through the stator windings, a magnetic field is created that interacts with the rotor field. This interaction results in a force that causes the rotor to rotate.

2. Rotation and its types

Constant rotation: In most motors, the rotor rotates at a constant speed, determined by the frequency of the alternating current or the switching speed of the windings. This rotation is used in devices with a constant load, such as pumps or conveyors.

Variable speed: In variable speed motors, the speed of rotation of the rotor can be varied, which is used, for example, in power tools or fans.

Positioning: In stepper and servo drives, precise control of rotation allows the motor to stop at a given position, which is important for robotics and automatic control systems.

3. Creating air flows

Motors are used to create air flows in fans, compressors and turbines. The basic principles of fan operation:

Fans: Blades fixed to the rotor of the motor create an air flow when rotating. Depending on the design of the fan, the flows can be directed straight (axial fans) or accelerated in a circle (radial fans). This is worth considering when you encounter them in the game.

Pumps and compressors: In these devices, motors drive blades or pistons, creating pressure and pumping liquids or gases.

4. Types of electric motors

There are different types of electric motors, each of which has its own characteristics and is used in certain conditions:

Asynchronous motors: Widely used in industry. Provide constant rotation of the rotor at a certain frequency of current.

Synchronous motors: The rotor of such motors rotates synchronously with the frequency of alternating current. They are used in devices that require a constant rotation speed.

Direct current (brushed and brushless): Motors with the ability to regulate the speed and direction of rotation. They are used in robotics, power tools and household appliances.

Stepper motors: Allow you to precisely control the position and angle of rotation of the rotor. Used in 3D printers, CNC machines and other precision mechanisms.

Servos: Compact motors with a feedback system that provide precise positioning and speed control.

5. Examples of using motors to create air flows and rotation

Ventilation systems: Axial and radial fans are used to create air flows in rooms, air conditioning and cooling systems.

Household appliances: In vacuum cleaners, dryers and kitchen hoods, motors create powerful air flows that perform certain functions (dust removal, drying or ventilation).

Industrial installations: In compressors and pumps, motors are used to pump liquids and gases, create a vacuum or pressure.

Used in unique games like Electron in the transistor-resistor kingdom.

Machines and transport: In electric cars and hybrid vehicles, motors provide movement, and in turbines of airplanes and helicopters, they create thrust and air flows.

6. Hazards when working with motors

Mechanical injuries: Rotating parts of the motor (rotor, blades) can cause serious injuries if they come into contact. Always use protective covers and guards.

Overheating: Motors can become hot if overloaded or if the cooling system is faulty. This can lead to failure or fire.

Electric shock: The operating voltages of motors, especially industrial ones, can be very high. When servicing, take precautions and disconnect the power supply.

7. Recommendations for operating motors

Check before starting: Make sure all motor parts and connected mechanisms are in good condition and installed correctly.

Routine maintenance: Perform regular maintenance, including lubricating bearings, checking connections, and cleaning vents.

Use of protective devices: Use fuses, thermal relays, and circuit breakers to protect the motor and circuit from overloads and short circuits.

Electric motors are important components of most modern machines and devices, providing rotational motion and creating air flows, which can be encountered when passing this level in the game. Their correct operation and maintenance allow you to achieve high efficiency and safety in work.

Related games

Electron in the transistor-resistor kingdom

Game: Perform tasks and rest cool. 2525 people play!

Play gameRelated news

Online broadcast about the game Electron in the Transistor-R...

broadcast about the game Electron in the Transistor-Resistor Kingdom

Read morePlatforms in the game Electron in the Transistor-Resistor Ki...

Platforms are the basic game elements in the platformer genre. They are surfaces or objects on which the player can move...

Read moreTeleport as a device for moving matter in space and time

This is a high-tech device that can instantly move a player from one point in the game world to another using plasma tec...

Read more